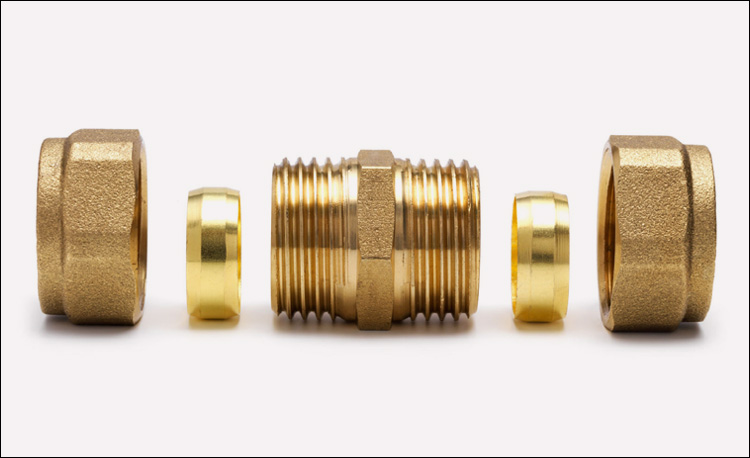

Capabilities

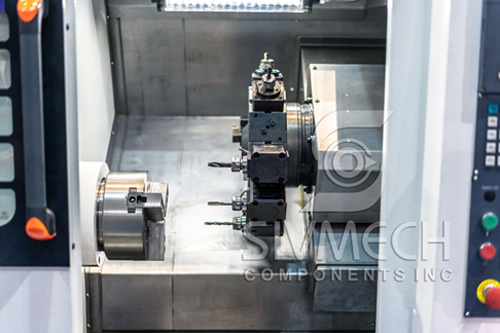

Machining Capabilities

SIVMECH COMPONENTS INC has the most modern CNC machining centers on the market. With this innovative and extensive machine park, SIVMECH COMPONENTS INC sets standards in terms of manufacturing technology and precision. SIVMECH COMPONENTS INC is able to manufacture individual and series parts for mechanical engineering as well as highly complex components for prototype and production.

SIVMECH COMPONENTS INC is capable of machining rod sizes from diameter 2mm to 200mm, forged components from 0.02kg to 5kg.

Materials For CNC Machining

SIVMECH COMPONENTS INC is capable of machining a wide range of materials which is best suited as per customers’ application and requirement. Few commonly used metals and thermoplastics includes.

Brass

CuZn39Pb3, CuZn40Pb2, CuZn36Pb2As, CuZn30/As, CuZn33, CuZn35, CuZn36, CuZn37/p, CuZn38As, CuZn40, CuZn42, CuZn39Sn1, CuZn14Si4, etc.

Copper

CW004A, CW114C, CW024A, CW118C, CW114C, etc.

Bronze

CC331G, CW306G, CW301G, CW307G, CW452K, etc.

Carbon Steel

1018, 117, 1141, 1144, 12L14, 1215, etc.

Steel Alloys

4130, 4140, 4340, 8620, 9310, etc.

Stainless Steel

303, 303SE, 304, 316, 316L, 13-8, 15-5, 17-4, 18-8, 321, 410, 416, 420, etc.

Aluminium

2011, 2017-T4, 2024, 5052, 6061, 7075, 7085, etc.

Thermoplastics

Delrin, Nylon, Acetal, ABS, Acrylic, PVC, etc.

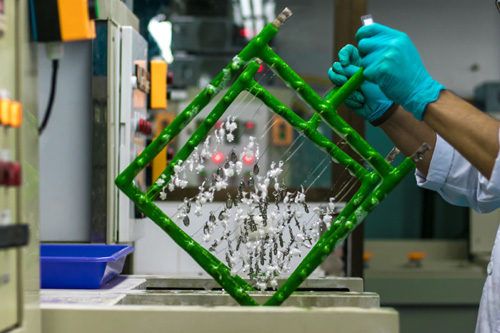

Assembly

Having a capable supplier machine your precision components and then use them to build your custom assemblies is the ideal manufacturing solution. Using the same team to manufacture and assemble your product can offer your operation the following advantages:

- Reduced Costs

- Reduced Labour

- Consistent Quality

- Increased Speed

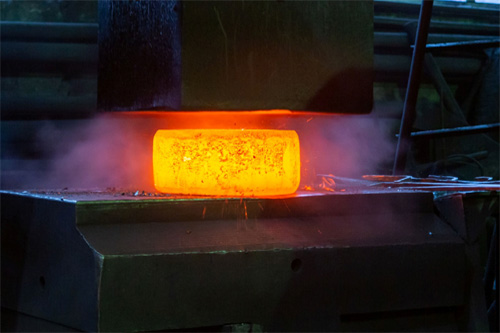

Outsourcing Capabilities

SIVMECH COMPONENTS INC can source Extruded Rods, Roll Milled Rods, all kinds of Casted & Forged products with ease. All kinds of surface treatments can also be performed on components as per the customers’ need.